Have you heard about robotization? Of course you have. To put it simply, it is replacement of manual work with machines. Where is robotization used? Robotization is possible not only on large industrial lines, but is also suitable for solving problems of small and medium-sized businesses. Almost any dirty, dangerous, monotonous work can and should be done by robots, not people. More info on deltronics.ch.

Problems solved by robotization of production

The coronavirus pandemic has highlighted the benefits of businesses equipped with automated lines. COVID-19, like other illnesses, is not scary for robots, and you can monitor the production process from a distance.

Experts believe that the widespread spread of the virus and the economic crisis it caused became the impetus for a new stage in the introduction of robotics in domestic industries. It is expected that by 2035 such factories will be able to produce 40% more products than today.

More details

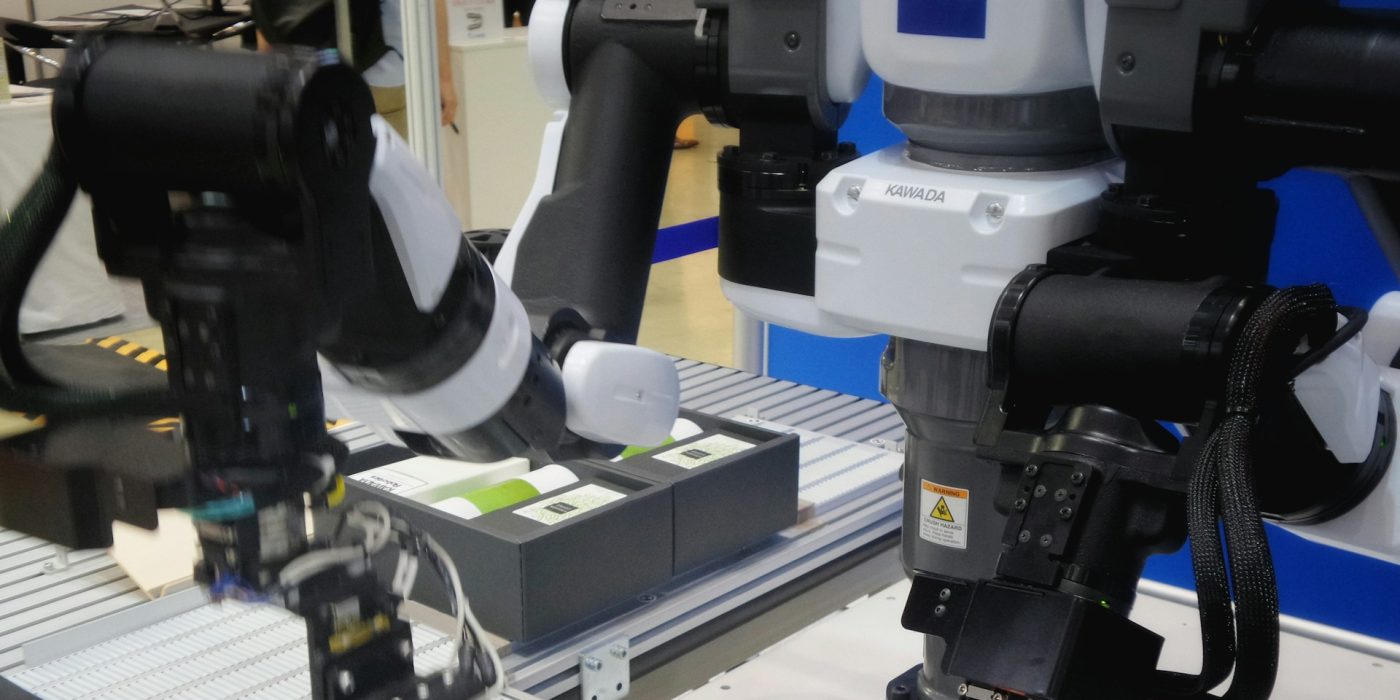

An industrial robot is capable of performing various functions in accordance with the program embedded in it. As a rule, we are talking about manipulating parts, delivering them to the conveyor, installing them in a unit, securing them in the right place, and so on. The automatic performer does not make mistakes, does not get tired, and does not require breaks for lunch or sleep.

What can be done by machines?

The list of technological operations performed by workers in industrial production is extensive. It includes casting, welding, manufacturing of parts on CNC machines, painting of workpieces, various types of assembly, and quality control.

Most of these works fit the basic postulate of robotization – compliance with the three Ds (dull, dirty and dangerous).

The following operations can be automated, which in many enterprises are still performed by people:

•welding work;

•supplying materials to the assembly line;

•moving components of a future product on a conveyor;

•sorting and packaging of finished products;

•product quality control;

•maintenance of CNC machines;

•placing products on pallets, moving to a warehouse, loading onto transport;

•surface painting;

•cutting materials and polishing products.

Robotization of industrial production can begin with the introduction of robotic manipulators into the process – industrial and collaborative.

Photo by Possessed Photography on Unsplash